What We Do

CONCRETE COUNTERTOPS

MARRIK HARDSCAPE Systems custom manufactures our client’s countertops using several methods:

* CAST in PLACE - the actual forming, casting and final finish is

performed on site in the final location. This system is well suited to large and/or intricate layouts.

* CAST off SITE - forming, casting and final finish performed in MARRIK’S

manufacturing facility.

TYPES of FINISHES

The finishes on your countertop are endless. They can incorporate any of the following:

- Colours: pigment in the actual concrete.

- Aggregates: assortment of sizes and mixes of colours e.g. granite, limestone and marble

aggregates.

- Glass: multiple choices of colours and sizes.

- Acid Staining: various colours of penetrating concrete stains.

- Burnished: hard steel trowel finish (no aggregate showing).

- Diamond Grinding: light exposure (showing ‘fine’ aggregate) or heavy exposure (showing

‘decorative’ aggregate).

- Specialty Items: metal shavings, sea shells, trivets and fibre optics.

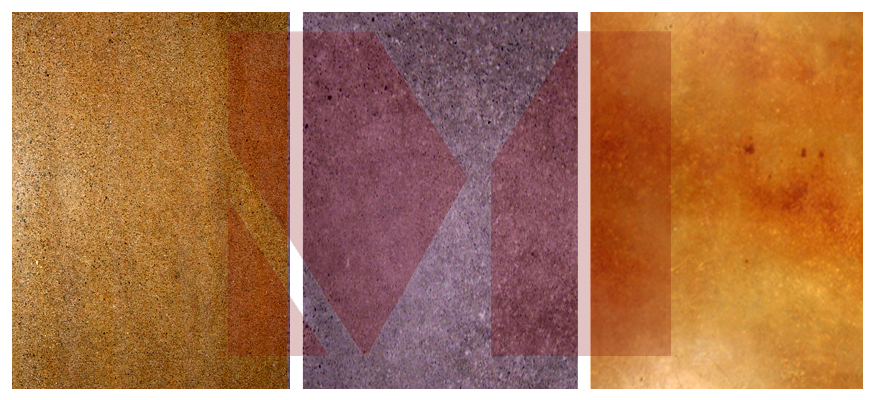

COLOURED ACID STAIN

Acid Staining is an affordable decorative system to enhance the appearance of natural coloured concrete.

The final finish achieved is a ‘mottled’, semi-transparent, coloured concrete using one or more colours of stains.

The stain creates a chemical reaction with all cementitious materials ensuring the colour becomes an integral part of the finished surface.

The stains may be applied to the following surfaces:

- new concrete.

- existing concrete.

- overlayment systems. (1/4”, 6 mm thickness)

EXPOSED AGGREGATE

Exposed aggregate concrete is an alternative to stamped / impressed concrete. The final appearance

is the natural look of a pebble / beach finish. MARRIK HARDSCAPE ‘SEEDS’ the surface of the

concrete with natural coloured stone ( granite, river stone, marble) to provide the customer with a complimentary colour accent to suit the overall design of the project. The decorative aggregate size is normally in the 3/8” to 3/4” range.

POLISHED / BURNISHED

Burnished concrete finish is achieved during the initial casting and finishing of the concrete.

The finished ‘burnished / polished’ systems incorporates a “glass” like concrete surface which has natural shading.

The concrete may be pigmented (coloured throughout) or natural concrete grey.

The completed surface has depth with out the appearance of a heavy lacquered look.

The ‘burnished’ finish may be installed during new construction OR as a bonded topping (1.5” minimum thickness) topping over existing base slabs for restoration projects.

OVERLAY SYSTEMS

MARRIK HARDSCAPE installs cementitious overlay systems. This product is normally 1/4” to 3/8” in thickness.

This product is used when an exposed concrete appearance is desired and the existing concrete slab is in an unacceptable condition.

The overlay is designed to be left exposed to foot and light industrial traffic. This product may be left natural concrete grey as

well as acid stained to create an artistic statement.

The industry proven product lines which MARRIK installs includes interior and exterior finishes.

FIREPLACE SURROUNDS / CUSTOM FEATURES

MARRIK HARSCAPES can custom manufacture many products and features. Please allow us the opportunity to view and discuss your designs and visions.

The design, uses and combinations of the above decorative systems are as endless as your imagination.

Please call to further discuss the design of your current or future projects.

info@marrik.ca

Back To Top

info@marrik.ca